Had a day off from work to help Bill out with some mapping today and discovered he had been a busy lad

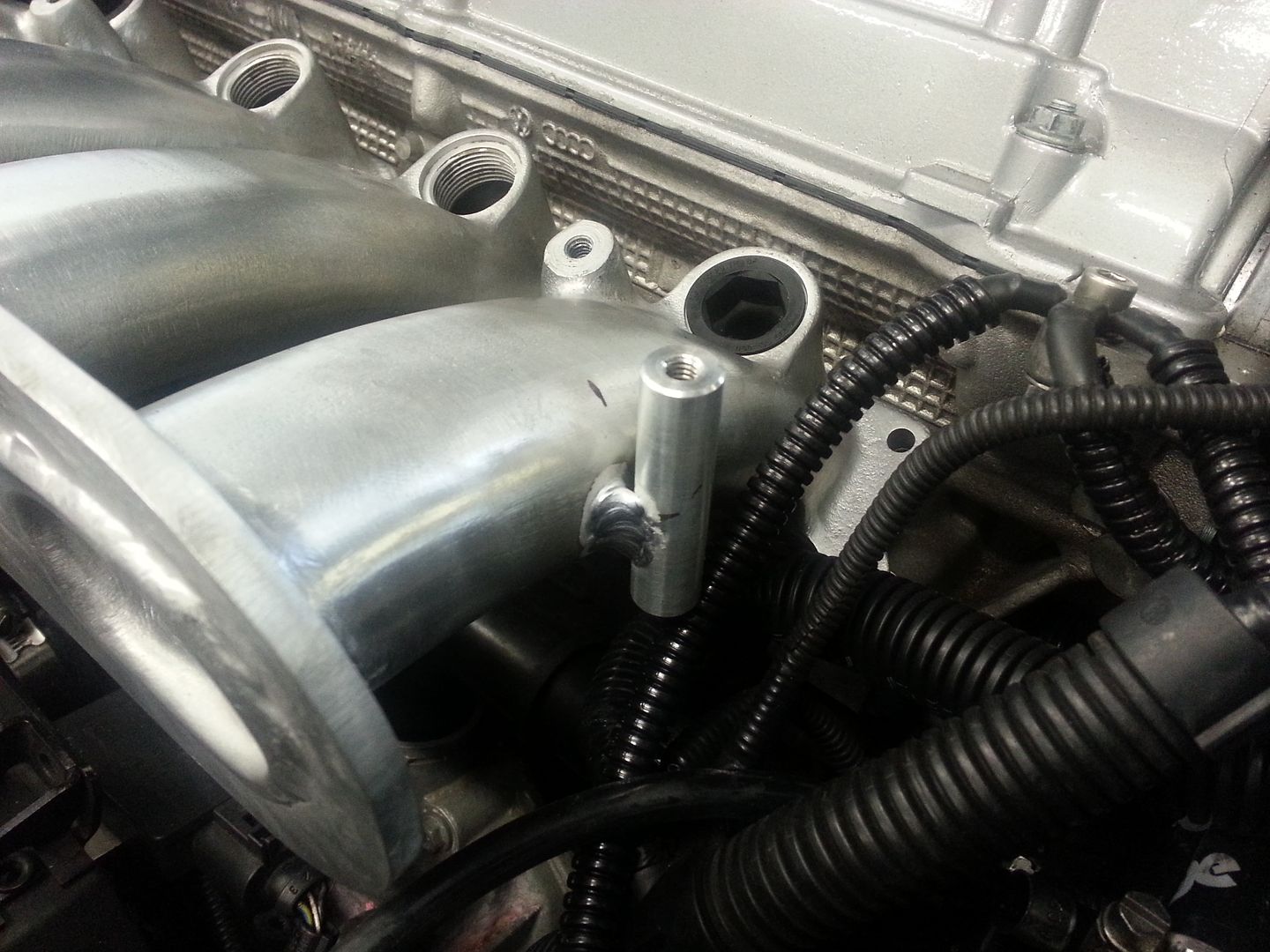

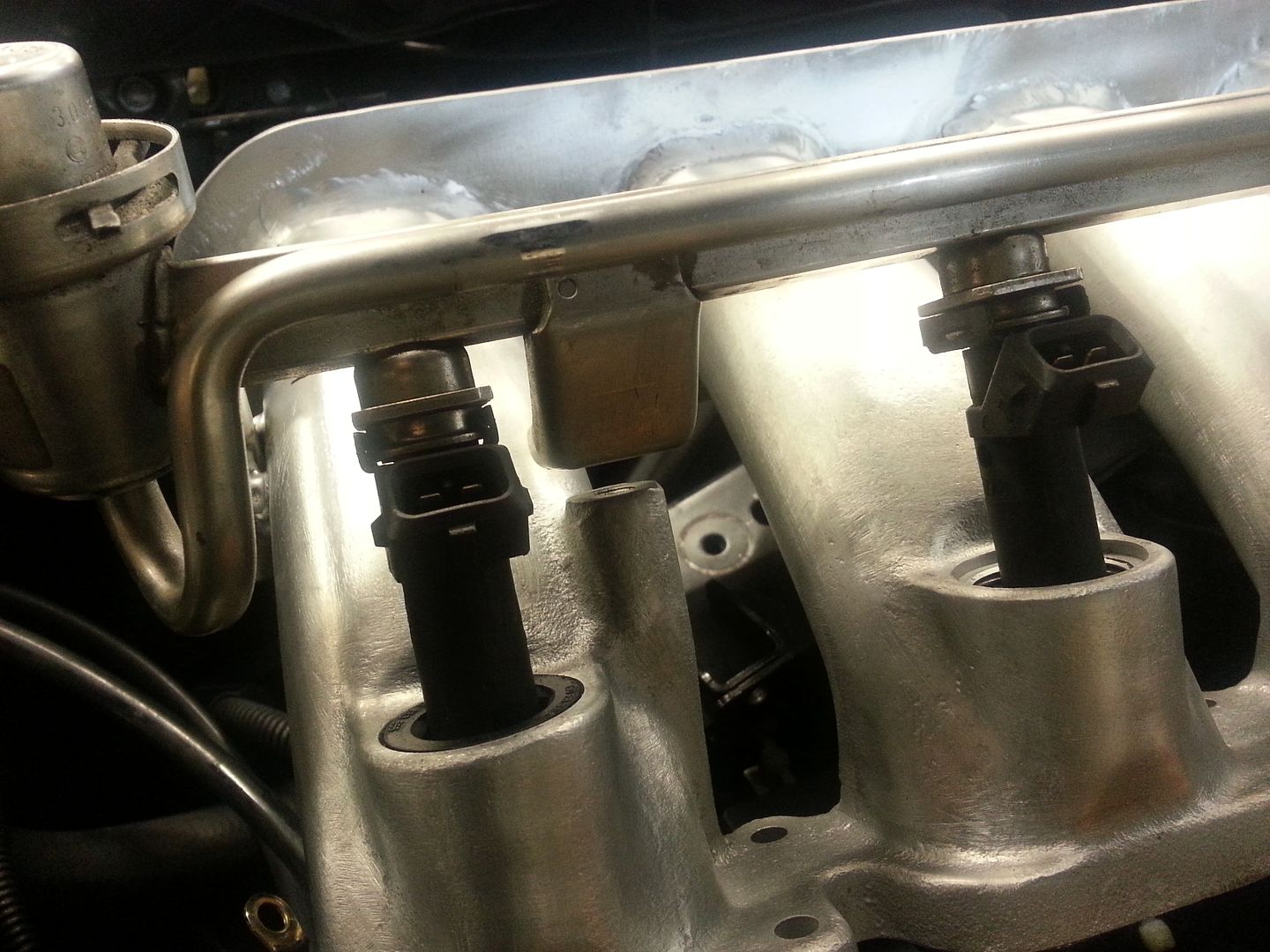

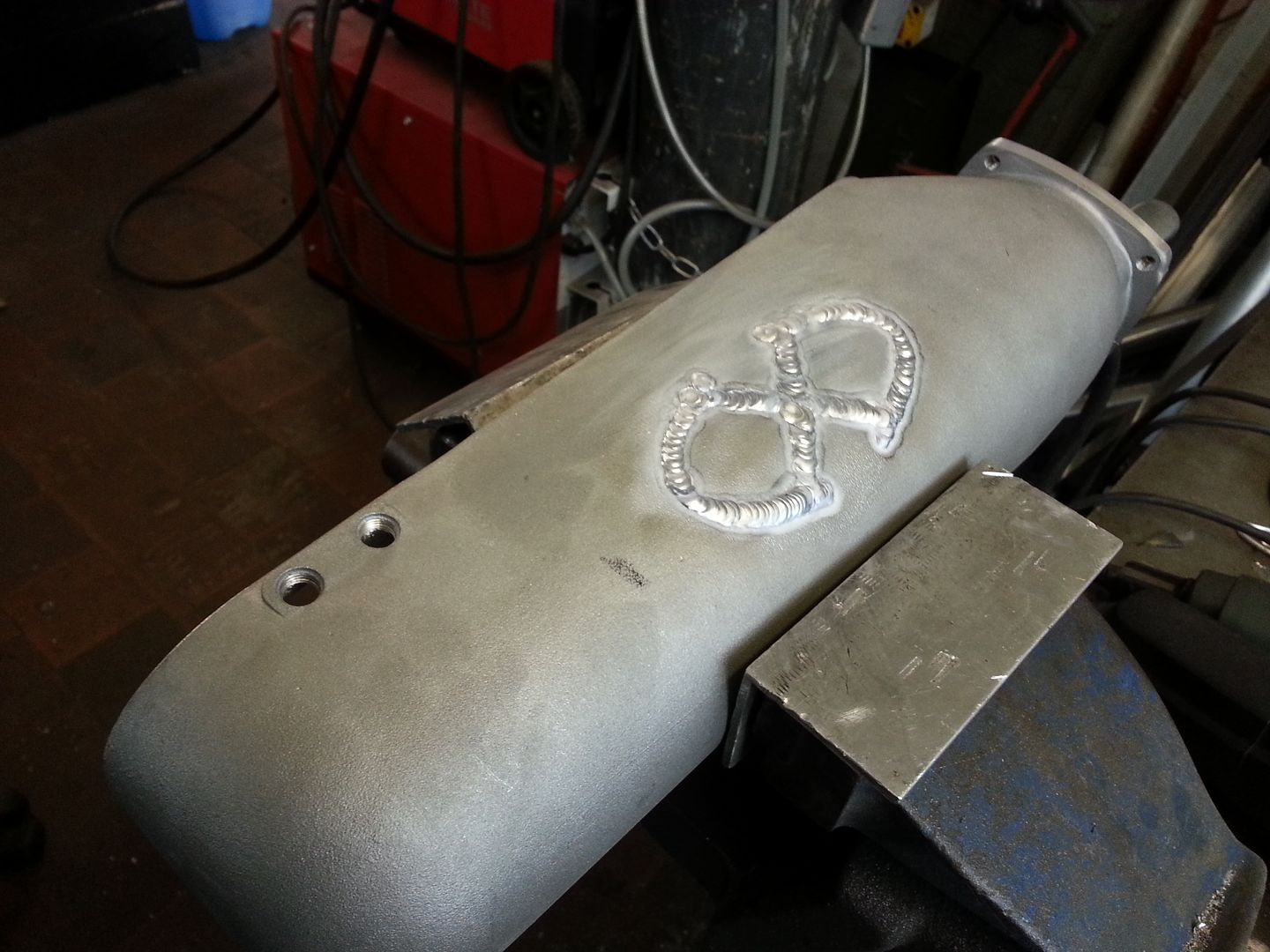

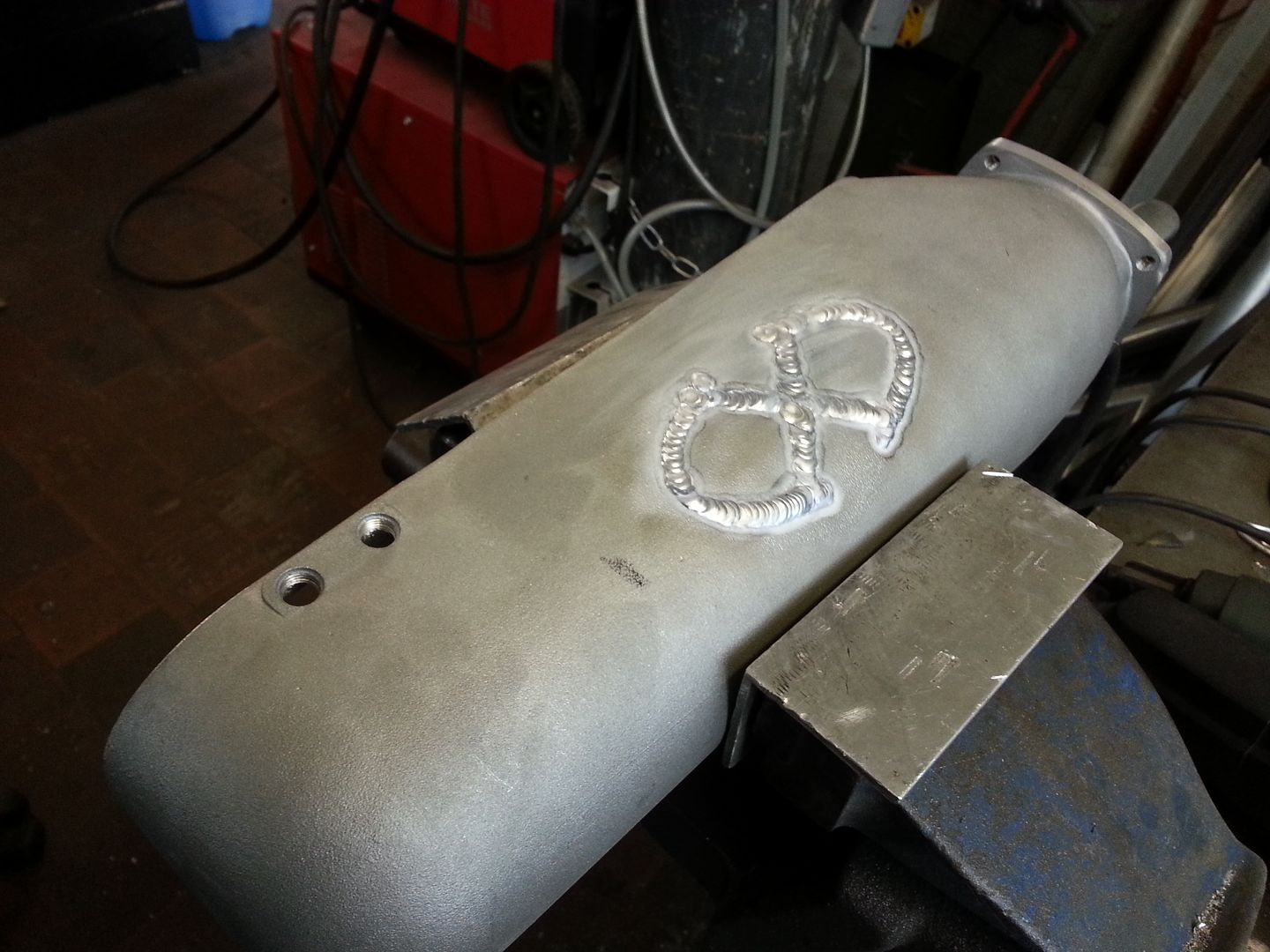

He had welded up the X for me on the plenum ready for smoothing... so I ground it down..

...and flushed the top set of vac ports...

Screwed in some threaded alloy bar and cut ready for welding...

Followed of course by a bit of grinding flush...

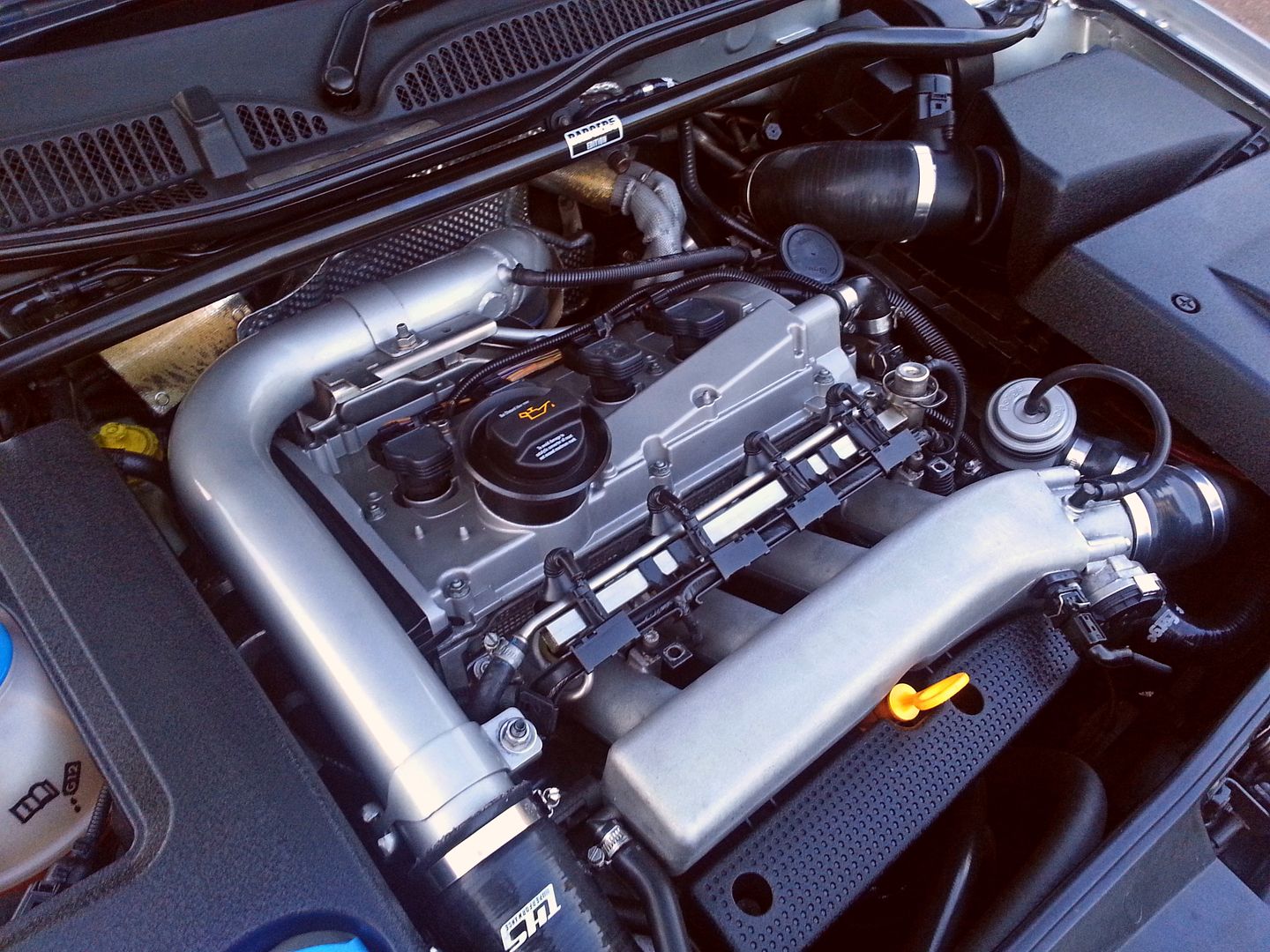

Excellent... now of course comes the 'fun' part of smoothing the texture of the plenum with lots of sanding

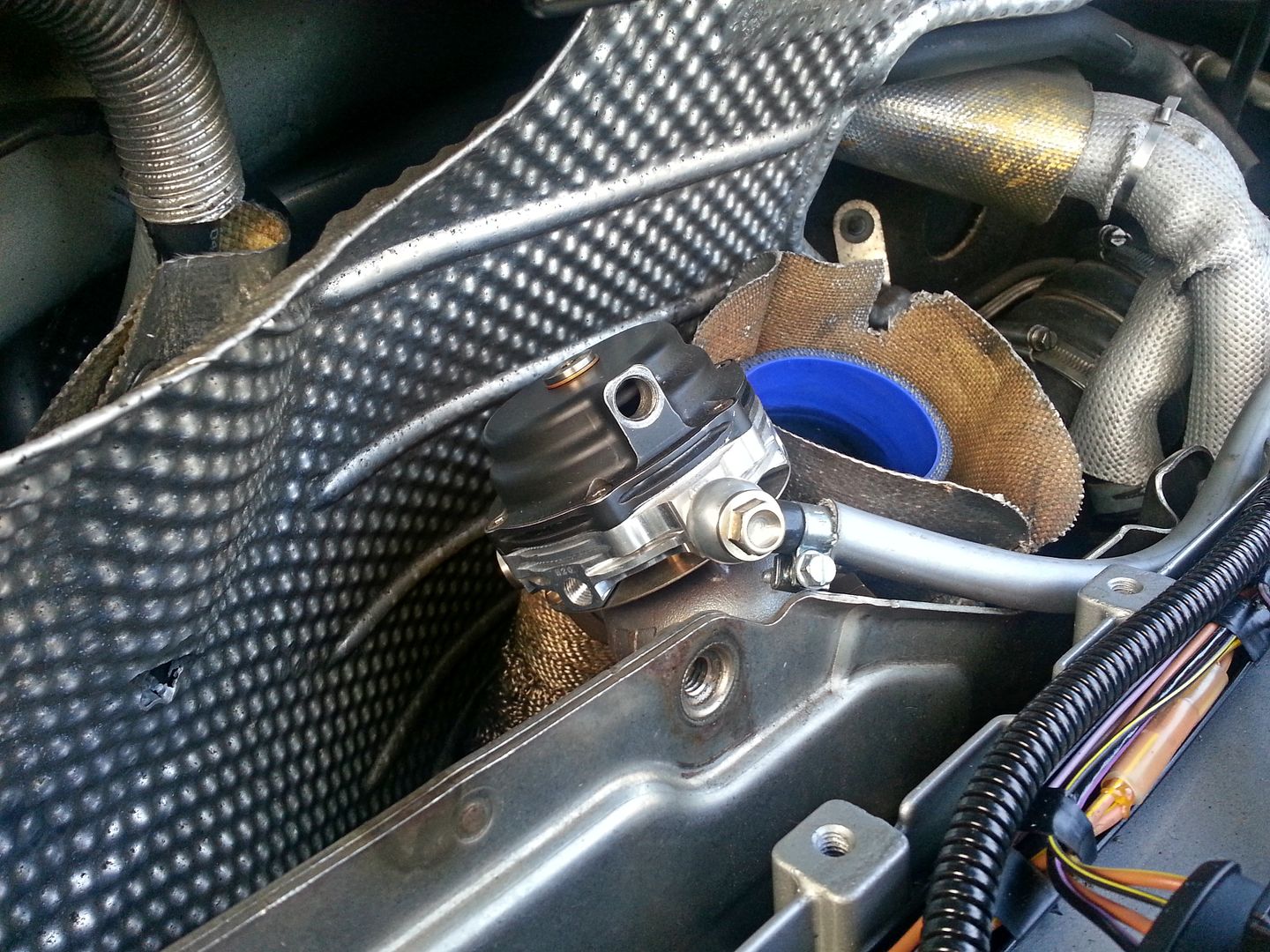

Also waiting on a bit of alloy plate to make the IAT sensor boss and vac ports and then of course welding the plenum to the runners... yay!

Big shout out to Bill of course for his TIG welding skillage and George for sorting out the threaded bar...

<tuffty/>

He had welded up the X for me on the plenum ready for smoothing... so I ground it down..

...and flushed the top set of vac ports...

Screwed in some threaded alloy bar and cut ready for welding...

Followed of course by a bit of grinding flush...

Excellent... now of course comes the 'fun' part of smoothing the texture of the plenum with lots of sanding

Also waiting on a bit of alloy plate to make the IAT sensor boss and vac ports and then of course welding the plenum to the runners... yay!

Big shout out to Bill of course for his TIG welding skillage and George for sorting out the threaded bar...

<tuffty/>