Project PD150

Some of you may know I’ve been modifying my golf over the years and edited this thread to show a bit up to date information.

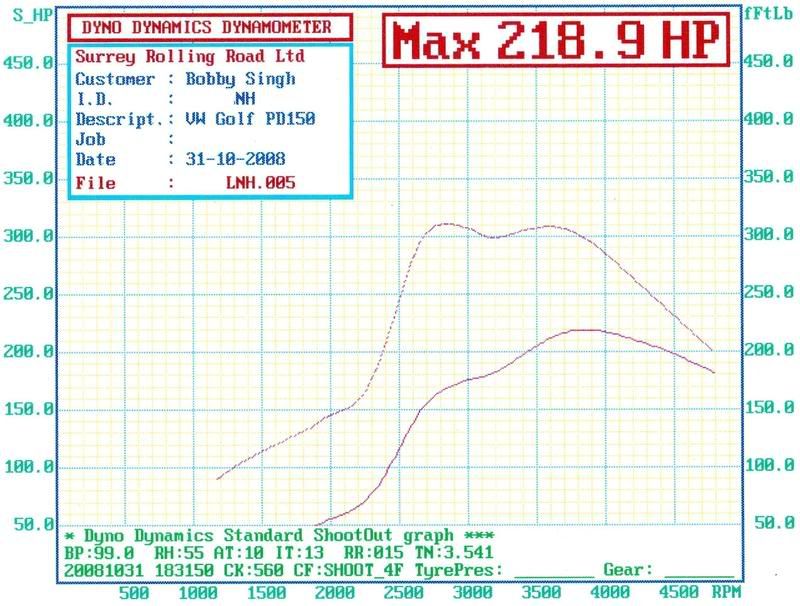

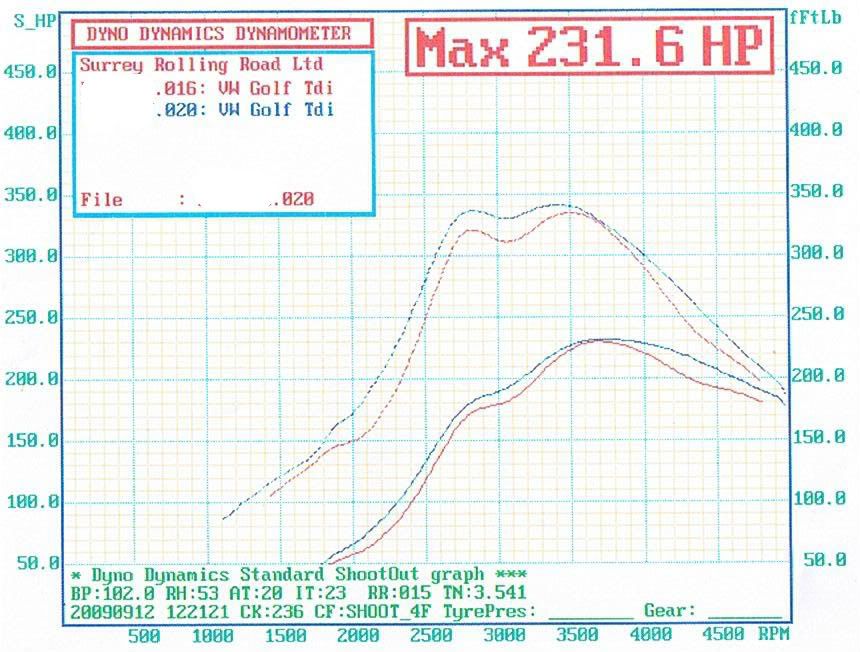

I ran the car on a stage 1 remap for approx 2 years. After this I done whole load of work and research to reach a MAX power figure of around 230hp. For anyone that reads this thinking 230hp is obtainable from a hybrid please think again as I had to run a very aggressive/unsafe map to get this figure. A true (and I mean a true power figure) for all VNT 17 based hybrids is around 220hp on stock nozzles.

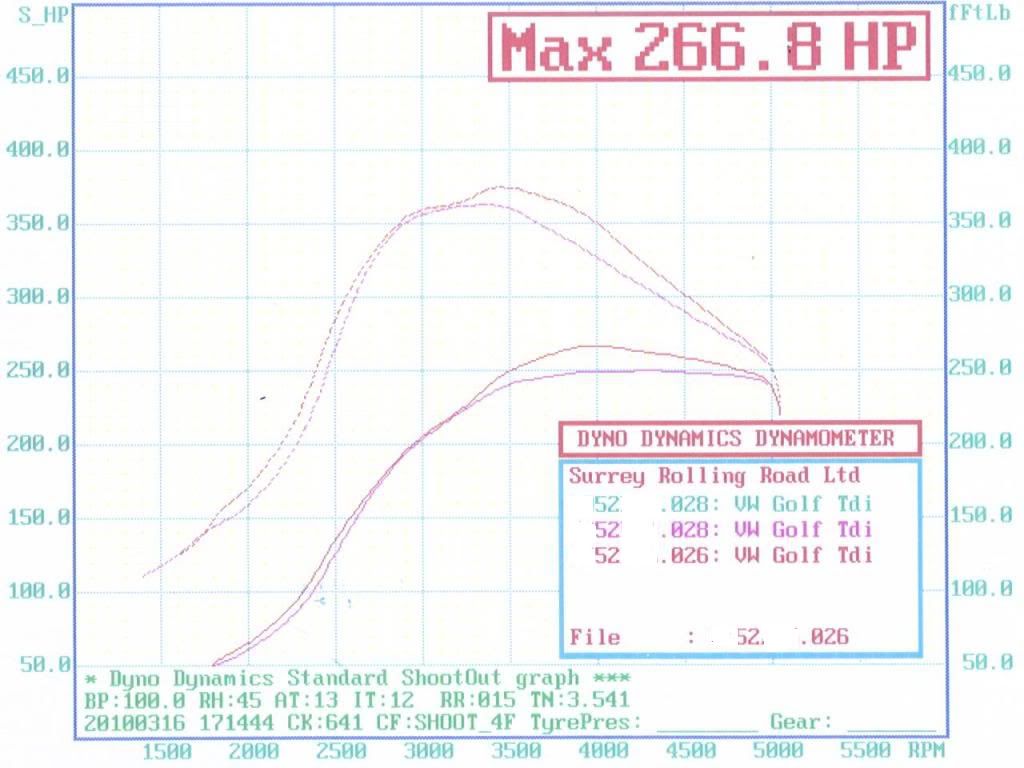

I have now moved away from VNT 17 hybrids a fitted a bigger turbo unit, bigger nozzles and lots of fabrication work.

Heres the story

March 2008 - Clutch

In addition a new Sachs Dual Mass Flywheel and release bearing were fitted.

April 2008 - EGR Replacement

Before

After

As I have blocked the exhaust manifold end I decided to remove all this (not had any problems with cabin heating):

May 2008 - 312mm Audi TT set up - these might look like scrap metal but they are actually in very good condition

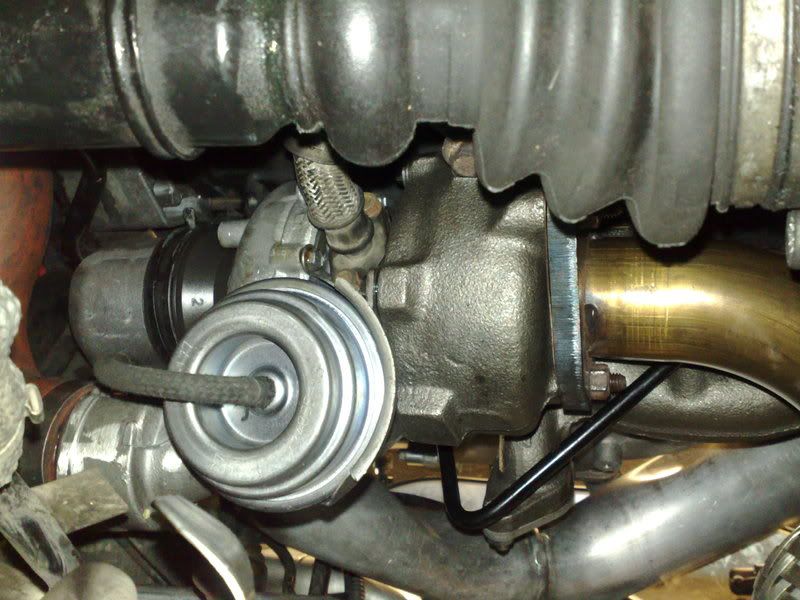

May 2008 - Hybrid turbo based on a VNT17 - with bigger exhast and compressor wheels

May 2008 - Turbo back Milltek exhaust system

May 2008 - New top suspension mounts (plus bearings), ARB bushes and 312mm set up fitted

Some of you may know I’ve been modifying my golf over the years and edited this thread to show a bit up to date information.

I ran the car on a stage 1 remap for approx 2 years. After this I done whole load of work and research to reach a MAX power figure of around 230hp. For anyone that reads this thinking 230hp is obtainable from a hybrid please think again as I had to run a very aggressive/unsafe map to get this figure. A true (and I mean a true power figure) for all VNT 17 based hybrids is around 220hp on stock nozzles.

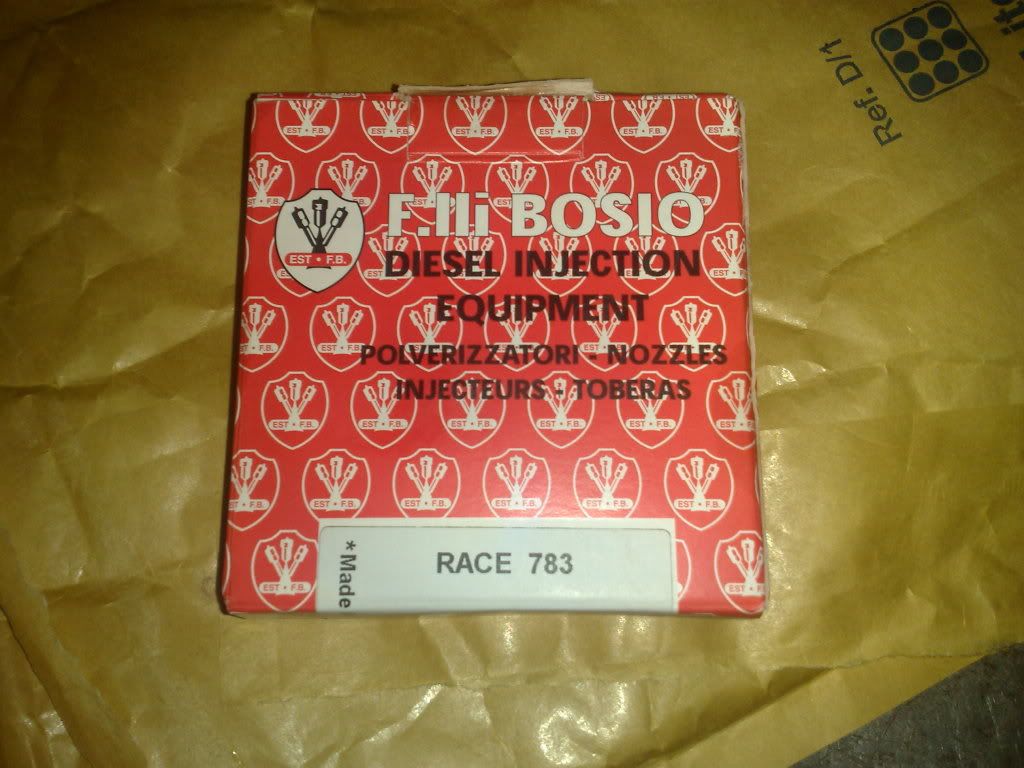

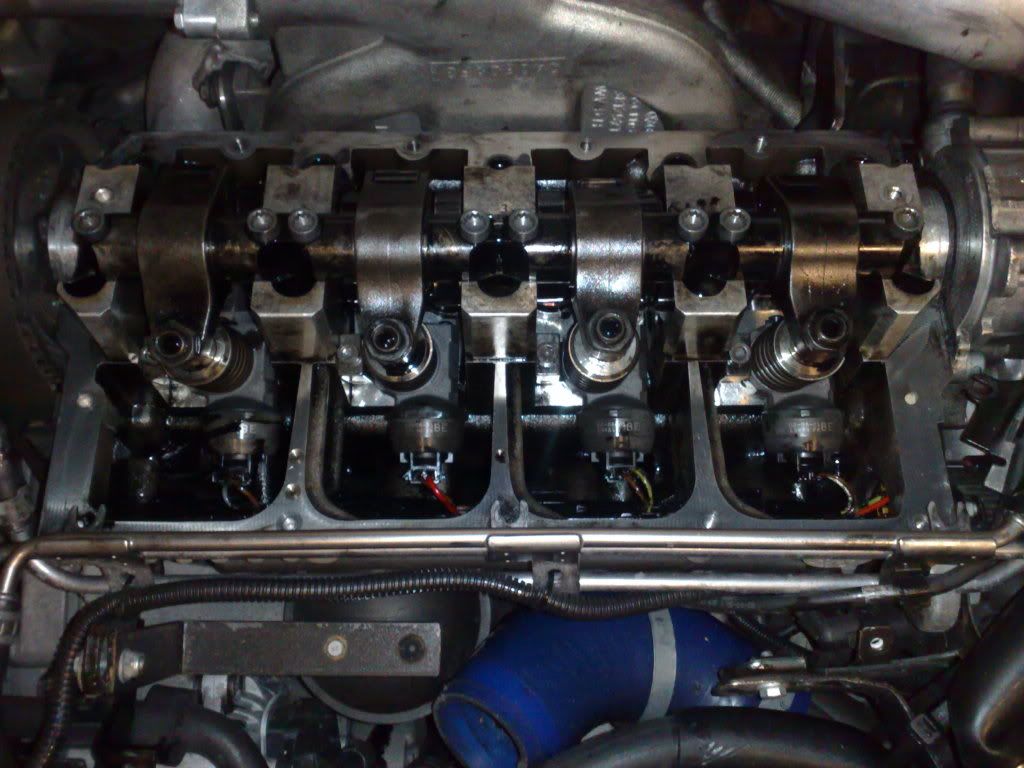

I have now moved away from VNT 17 hybrids a fitted a bigger turbo unit, bigger nozzles and lots of fabrication work.

Heres the story

March 2008 - Clutch

In addition a new Sachs Dual Mass Flywheel and release bearing were fitted.

April 2008 - EGR Replacement

Before

After

As I have blocked the exhaust manifold end I decided to remove all this (not had any problems with cabin heating):

May 2008 - 312mm Audi TT set up - these might look like scrap metal but they are actually in very good condition

May 2008 - Hybrid turbo based on a VNT17 - with bigger exhast and compressor wheels

May 2008 - Turbo back Milltek exhaust system

May 2008 - New top suspension mounts (plus bearings), ARB bushes and 312mm set up fitted

Last edited: